Description

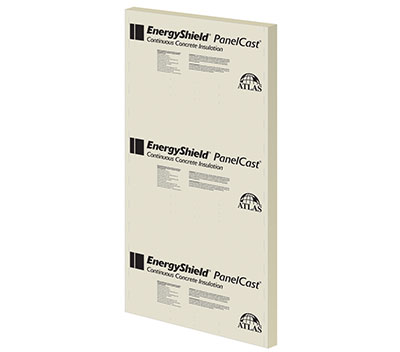

Atlas EnergyShield PanelCast is composed of a closed cell polyisocyanurate (polyiso) foam core, faced with a non-reflective coated glass-mat facer on both sides. The blowing agent used to produce the polyiso foam core does not contain any CFCs, HCFCs or HFCs. EnergyShield PanelCast has zero Ozone Depletion Potential (ODP) and negligible Global Warming Potential (GWP). Atlas EnergyShield PanelCast combines high R-value, enhanced durability from two coated glass-mat facers, and water resistive attributes in a high performance rigid wall insulation. EnergyShield PanelCast is suitable for a variety of continuous insulation (CI) applications in concrete wall systems.

Panel sizes are 4ʹ by 8ʹ or 4ʹ by 9ʹ. Panels can be supplied in nominal 16ʺ and 24ʺ widths. Custom sizes are also available.

| R-VALUE1,2 | NOMINAL BOARD THICKNESS3 |

|---|---|

| 12.1 | 2.0″ |

| 15.3 | 2.5″ |

| 18.5 | 3.0″ |

| 21.7 | 3.5″ |

| 25.0 | 4.0″ |

1Thermal values were determined by ASTM C518 Test Method at 75°F mean temperature using materials conditioned in accordance with ASTM C1289.

2“R” means resistance to heat flow. The higher the R-value, the greater the insulating power.

3Additional sizes available upon request. EnergyShield PanelCast is shipped on standard 48ʹ truck with 24 packages per load. Truckload quantities may vary when mixed.

EnergyShield PanelCast is recommended for use in insulated concrete panels, forms and tilt-up walls in commercial and residential construction applications, check local building codes for compliance. The coated glass-mat facers enhance the product’s durability and are more permeable than foil facers.

Common applications include:

- Precast insulated concrete sandwich panels

- Continuous insulation in concrete wall systems

- Insulation for use in precast, tilt-up and cast-in-place insulated concrete wall panels

- Under slab insulation

- Various OEM applications

| PROPERTY | TEST METHOD | TEST METHOD MINIMUM REQUIREMENTS |

|---|---|---|

| COMPRESSIVE STRENGTH | ASTM D1621 | 25 psi |

| FLAME SPREAD | ASTM E84 /UL 723 | ≤75 |

| SMOKE DEVELOPMENT | ASTM E84 /UL 723 | ≤450 |

| WATER VAPOR TRANSMISSION, METHOD A | ASTM E96 | 1.2 Perm at 1-inch |

| WATER ABSORPTION | ASTM C209/ASTM C1793 | <1% by Volume *Typical Results <0.5% by Volume |

| DIMENSIONAL STABILITY, LENGTH & WIDTH | ASTM D2126 | ≤1% Linear Change *Typical Results <1% Linear Change |

| SERVICE TEMPERATURES | – | -100°F to +250°F (-73°C to 122°C) |

| MOLD RESISTANCE | UL 2824 | 4, Highly Resistant |

Technical and physical properties listed are representative of typical values based on testing and are intended as general guidelines only and subject to manufacturing tolerances.

No warranties are given except for those specifically written by Atlas for its products.

- ASTM C1289 Type II, Class 2

- ASHRAE 90.1

- ASHRAE 189.1

- International Energy Conservation Code (IECC), Section 402

- International Green Construction Code (IgCC)

- International Building Code (IBC), Section 2603

- International Residential Code (IRC), Section R316

- California Thermal Insulation Directory, T 1231

- ICC-ES ESR-1375

- ASTM E84/UL 723, Class B